Intro:

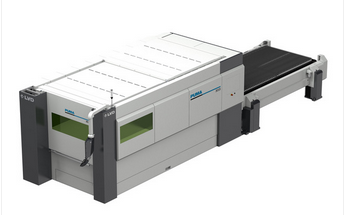

CNC machine tools are personal computer-handled machinery utilized in many different developing sectors. They are used to make factors in a wide array of components for example metal, plastic, timber, and window. Employing CNC devices offers manufacturers the capability to produce higher-top quality parts with constant accuracy and reliability and repeatability while decreasing metal working tools production efforts and expenses. On this page, we will go over a number of the fundamentals of knowing CNC machine tools and how they can aid your organization.

How CNC Models Job

CNC means Pc Numerical Handle. A CNC device resource is largely a personal computer-controlled device which utilizes numerical details to regulate its activity along three axes—X, Y, and Z—to create accurate pieces or shapes. The complicated system manipulating the machine is known as “G-rule,” which shows the appliance where you can transfer its decreasing brain relative to the x, y, and z-axis details. The G-code guidelines also tell the appliance how fast it should transfer between these factors, which kind of instrument needs to be used for cutting (such as a drill or router), just how much material should be taken from each position around the aspect becoming machined (called supply elimination), how deep each cut ought to be produced (named level of lower), and other guidelines. With this particular info programmed into the pc manipulating the CNC unit resource, it could correctly create elements that meet up with customer features with very little handbook treatment essental to an operator.

Advantages of using CNC Devices

Employing CNC models has several advantages over traditional methods including hands machining or handbook milling machines. To begin with, since all movements are computerized by pc programming as an alternative to man feedback, no user exhaustion is introduced into the procedure which can cause problems in creation good quality or number. Furthermore, because all operations are programmed in the laptop or computer prior to time—including velocity settings for every single operation—CNC equipment can operate at increased rates of speed than guidebook machines without diminishing accuracy and reliability or basic safety. This will significantly decrease generation time per component and increase throughput costs for companies generating a number of pieces in large quantities. Ultimately, simply because G-code courses might be preserved on a hard disk or USB push for potential use, when a portion has been made it’s an easy task to reproduce actual duplicates while not having to manually re-system each step from scratch—saving both time and expense!

Bottom line:

Comprehending CNC Machine Tools is crucial for virtually any company planning to improve its manufacturing operations through automation and greater effectiveness. Not only do these machines offer you increased reliability over traditional methods for example hands machining or guidebook milling models but they also decrease manufacturing occasions per component due to their automated coding functionality permitting enterprises to quickly turn around multiple purchases without having to sacrifice quality management standards or profits margins. By making the most of these traits made available from contemporary-day CNC technological innovation enterprises can stay aggressive in today’s ever-changing market place while still delivering clients with high quality items at competitive prices!